|

Controls, Inc. Controls, Inc.

|

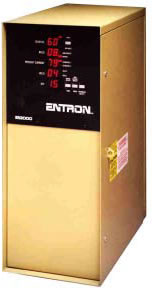

Controls for Resistance Welding EN2000 Dual Schedule/Dual Sequence S2H Controls

|

Features

- Spot Sequence

- Dual Weld/Dual Current Sequence

- External Schedule Select

- Error Outputs

- LED Status Indicators

- All Functions Displayed

Simultaneously

- Optional Manual Current Adjust

- Hierarchical Initiation Structure

|

Capabilities

- Two Schedules

- Repeat & Non-Repeat

- Weld & Valve Control Relays

- One Valve Output

- Dual Weld Programming

- Easily Programmed

|

|

Unique to ENTRON. All

EN2000 Single Contactor

Control in D or T cabinets

feature provisions for field

installation or change of circuit

breakers. |

Advantages

- Simple to Program

- Direct Reading Digital

Data Display

- Simplified Design

- Quality Tested to

Performance Extremes

Each unit is tested to its maximum

capability to assure performance at

customary operating levels.

ENTRON is the only resistance

welding controls with the excellent

performance history.

- Dedicated Dual Schedule/

Dual Sequence Controls

Designed for use with single phase

welding machines, rocker arm,

press type welders, robotic

equipment, and special machines.

- Design Simplicity

Design simplicity is the key to our

ability to manufacture the highest

quality weld control with the best

delivery, least maintenance, and

lowest out-of-warranty service in

the industry.

- Field Expandable

ENTRON can provide retrofit

controls suitable for any

manufacturer's controls of any

age, type or sequence for

installation in the field.

- Vault Closing Door

Mechanism

D & T cabinet doors equipped with

vault locking mechanism to ensure

security.

- Applications

EN2000 Single Contactor Controls

can be applied to spot welders,

special machines, or robotic

equipment for welding.

- Multiple Cabinet Options

Available in D & T cabinet styles

with front or side-mounted control

panels.

|

|

|

|

|

Entron Controls, do not weld without them!

|

|